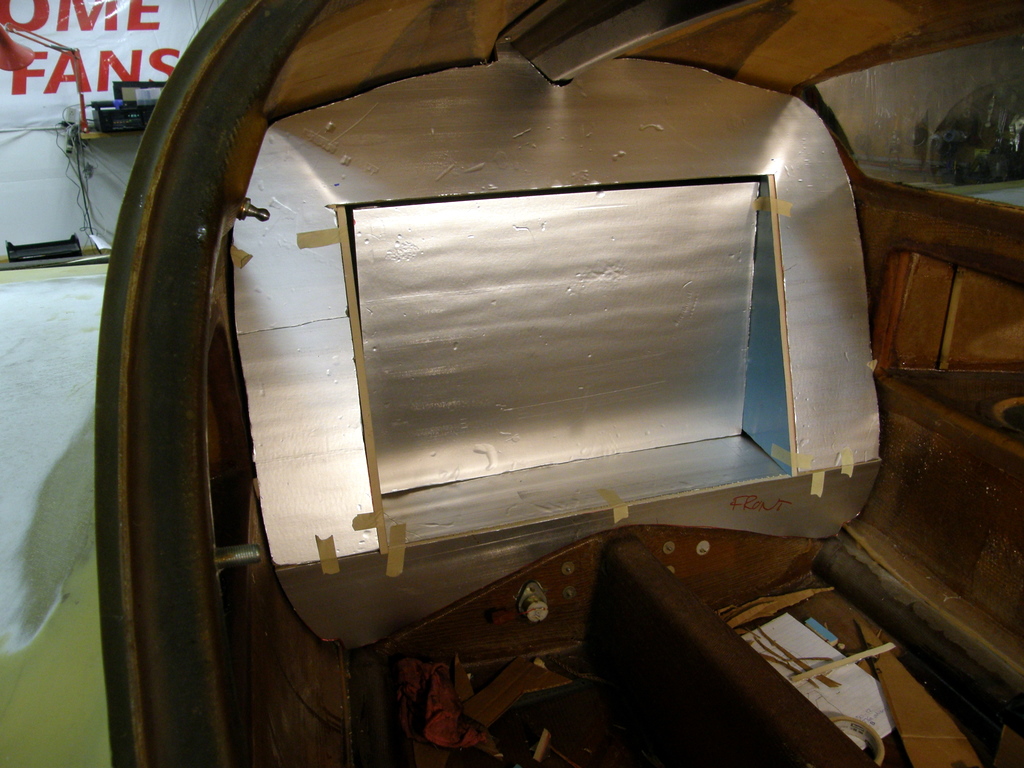

After consulting with a few Velocity builders on the different ways to close off the firewall and create a package shelf, I got started. This is my first fiberglass work on the plane. Good place to start as I am just building interior panels and nothing structural. I first cut 1/2″ foam to fit in the I wanted. That was tougher than I thought – getting the right profile of the interior fuselage was a challenge. After I cut the main shape and had it fitting nice, I removed ~1/8″ all around to accommodate the width of the upholstery. I will cutout the the horizontal package shelf to make a hinged inspection area and do the same for the vertical part so the RG can be easily inspected. Once all foam was cut out I laid out one layer of BID on both sides of all parts. I am using the EZ EPOXY brand with the EZ 83 hardener which is supposed to cure in 24hr (@77F). I thought it would be pretty much set by morning but it was still pretty flimsy but my shop was ~65F, so I made a plastic blanket over my table and added a heat lamp to bring it up to ~80C.

Read this next